Initial Production Check (IPC) for Pre-Production Quality Control

Ensure a smooth production process by addressing potential issues early.

QIMA’s initial production check is a comprehensive on-site inspection conducted from pre-production through the first 20% of the production progress. This service ensures that your production is not exposed to delays, defects, unauthorized subcontracting, and supplier non-compliance.

On this page, you will find:

What is an Initial Production Check (IPC)?

Why Perform an IPC?

What Checks are Carried Out?

What are the Next Steps after Completing an IPC?

QIMA Expertise

QIMA Benefits

Need more information?

By contacting QIMA you agree to our privacy policy and terms and conditions.

What is an Initial Production Check (IPC)?

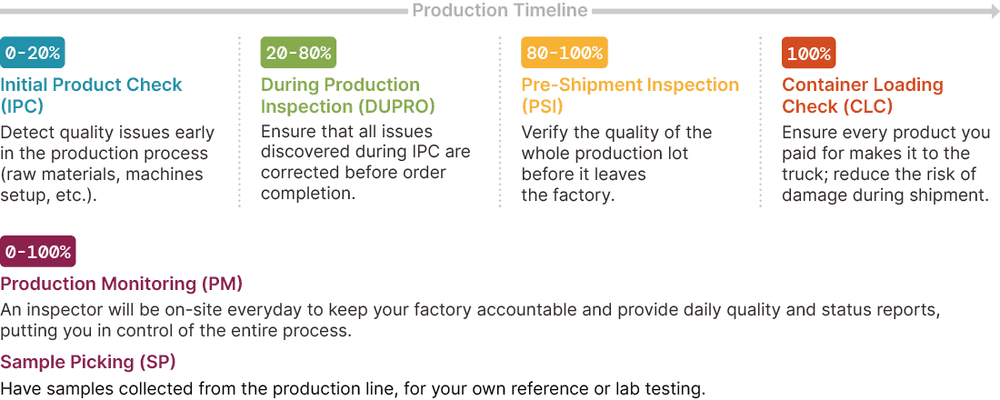

An IPC is an on-site product inspection performed from before your production begins up until 20% has been completed.

In an IPC inspection, inspectors check the quality of raw materials and the first items produced in a production run. These checks are used to identify quality issues early on in production and to prevent them from causing bigger issues further down the road.

Why Perform an IPC?

There are several important reasons to use an IPC inspection:

Enforce quality standards early and benefit from an early-warning system for potential issues.

Reduce the likelihood of having to correct defective products at the end of a production run.

Identify and potentially mitigate disruptions that may arise at the start of production.

Verify the quality of supplied raw materials.

Ensure that the factory has properly set up the production run and fully understands your brand’s specifications.

Gain confidence that quality standards will be met.

What Checks are Carried Out?

At the outset, the QIMA inspector will begin by randomly selecting a sample of products for inspection, in line with the ANSI/ASQ Z1.4-2008 sampling standard.

Following sample selection, inspections are customized to meet client requirements and the specific product type. QIMA offers a wide range of pre-designed inspection checklists tailored to various products, which clients may use “as-is.” Alternatively, clients can modify these checklists by adding specific checks or create an entirely unique checklist to meet their precise needs.

Initial Production Check (IPC)

QIMA conducts a comprehensive pre-production inspection that involves a series of meticulous checks, typically including the following:

Raw material and production process check

Raw material quantities

General storage conditions

Manufacturing processes

Production organization and status

Product specifications checks:

Quantities of semi-finished, finished, and packed products

Product colors, style, and construction

Artwork, including spelling, fonts, dimensions, positioning, and general design

Labels including main labels, care labels, size labels, and product tags

Product dimensions check

Other product-specific checks and tests to verify quality and workmanship

Packing and packaging checks:

Unit packing

Inner and outer packing

Export carton dimensions and weights

Shipping marks on cartons

What are the Next Steps after Completing an IPC?

Once the Initial Production Check is completed, you'll receive a detailed inspection report the same day. You’ll be able to access the report through your online QIMA account. The report details the inspection findings, includes photos of any defects, and gives an overall pass/fail assessment.

It’s important to note that while an IPC helps set production off to a good start, it alone cannot ensure the quality of finished products. We recommend combining an IPC with a Pre-Shipment Inspection (PSI), which checks the products after the full quantity has been produced. Without a PSI, there’s a risk that poor-quality products could be shipped despite the IPC.

QIMA Expertise

QIMA provides independent quality control designed to protect your business interests. Our highly trained and experienced inspectors are product experts who undergo regular training in their field of specialization. They can be onsite at your factory within 48 hours of booking, and reports are provided on the same day as the inspection.

Our inspections cover a full range of consumer products, including but not limited to apparel, footwear, toys, electronics, and furniture.

Create an account and book an IPC

Take Your Quality Management Online

QIMA offers an intelligent online platform to help you seamlessly manage your quality control and global supply network.

You can easily book, cancel or reschedule inspections, make payments or download your inspection reports with a few clicks. We also provide a customizable dashboard with all of your quality control data, so you can identify trends and make informed decisions in real-time.

QIMA Benefits

Independent quality control performed by product experts to protect your business interests.

Global coverage across 100 countries in Asia, Africa, Europe, North and South America.

Speed and flexibility with an inspector onsite within 48 hours; modify or cancel up to the day before inspection.

Same-day inspection reports tailored for your product.

Online program management to book inspections, make payments, and download detailed reports.

Custom quality dashboard to identify trends and make informed decisions in real time.

Ranked #1 in the industry for customer satisfaction based on independent NPS measurement.